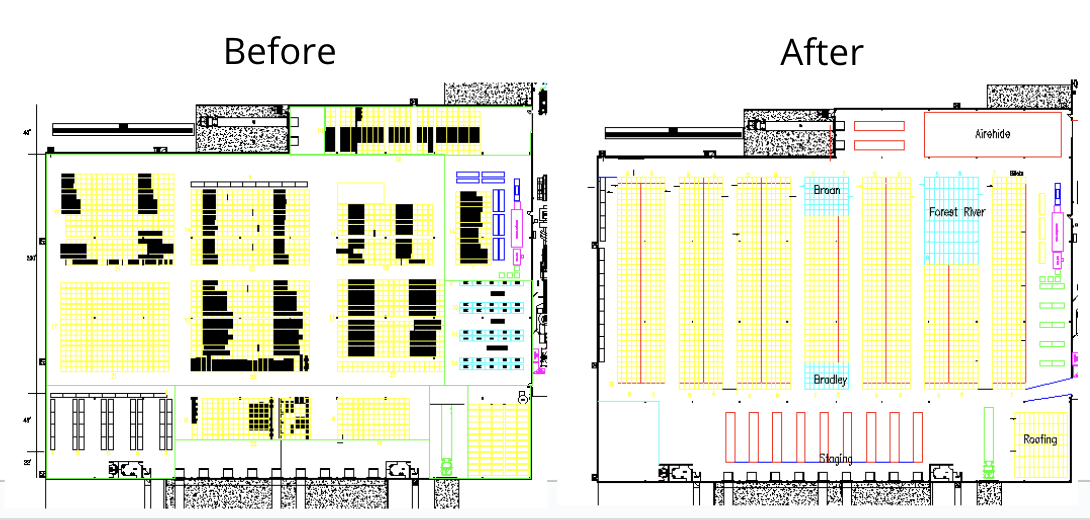

Challenge

Our mid-sized packaging manufacturer’s plant was running out of space and congested. The 123,000-square-foot storage area is located in between inbound/outbound dock doors and packaging production work cells. There was significant congestion with material staged in aisles, lots of double-handling, product damage and partially filled locations. The client said, “I would like help to lay out the warehouse space and make product flow better to the dock and also gain more usable square footage.” Forklift drivers complained about digging for pallets and excessive travel.

Approach & Actions

3PLR’s work started with inventory analysis of on-hand, demand and velocity, as well as palletization, handling and cubic dimensions. 3PLR evaluated storage capacity compared to current storage utilization. Analysis revealed a honeycombing factor of 32% over 240 stows and 10,450 feet of staging, which was tight. 3PLR estimated the number of facings and the right amount of product on-hand required to meet current and forecasted demand. These are key inputs for warehouse slotting, along with a good sense of material flow design.

Results

3PLR leveraged inputs to develop a new layout and compared the results to baseline. The layout design achieved 21.5% increase in storage, with 228 more stows, and staging increased by 93% to 20,200 SF.

Ready to optimize your strategy?

Contact 3PLR or schedule a call to discuss your company's needs and find the right solution to optimize your operations.